Selecting the Right Defoamer for Your Details Application Demands

Choosing the appropriate defoamer for particular application demands is a nuanced process that demands mindful consideration of numerous aspects, such as the foam operating, tool, and type problems. Recognizing the subtleties of defoamer efficiency-- consisting of speed and persistence-- while also making up environmental and regulative aspects is crucial. Furthermore, taking part in trials and speaking with producers can supply important insights. Nevertheless, browsing these complexities can be overwhelming, and the effects of a poor selection might be significant. What techniques can be utilized to guarantee an optimal option?

Comprehending Foam Formation

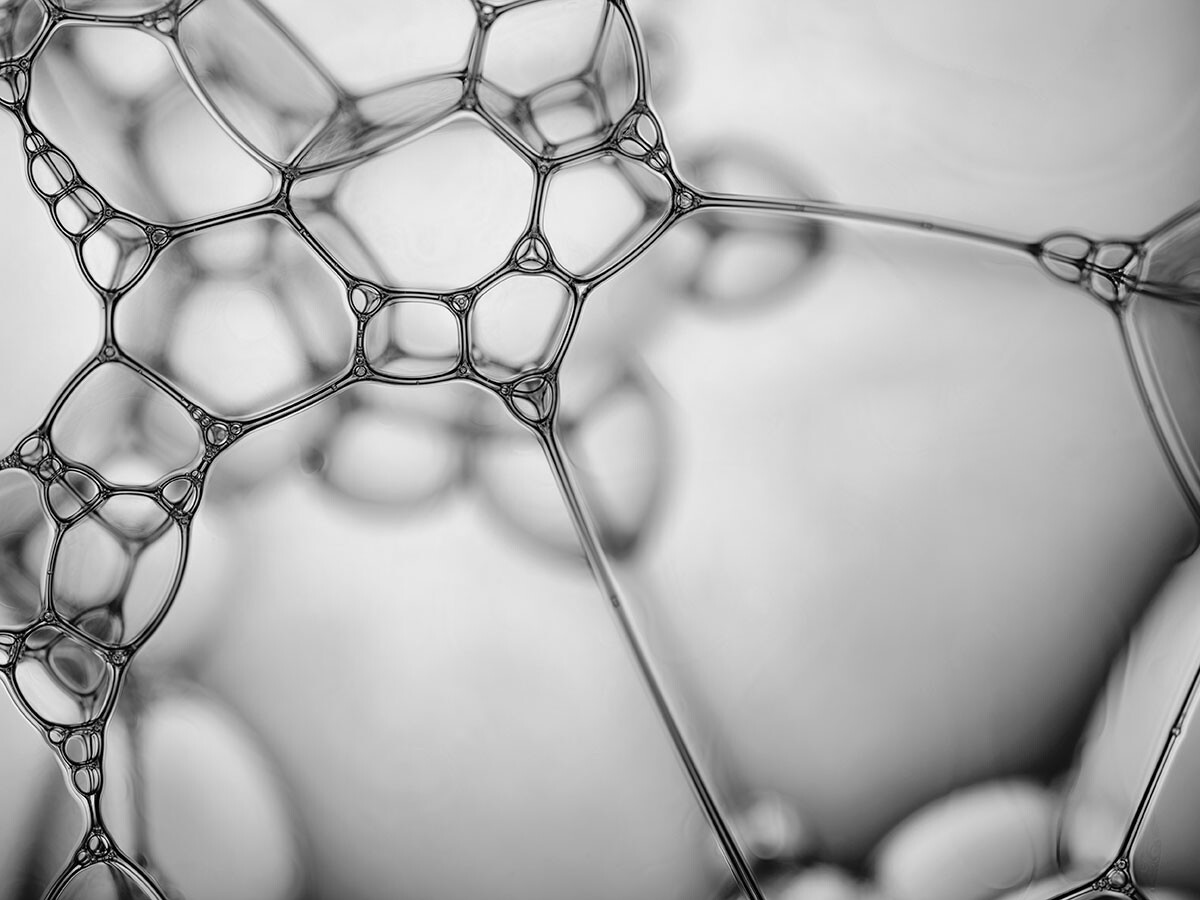

Foam development happens when gas is caught within a liquid, producing a secure framework of bubbles. This sensation can substantially impact various industrial procedures, particularly in sectors such as food manufacturing, drugs, and wastewater therapy. The existence of foam can impede mixing, lower product quality, and also cause operational inadequacies.

Foam generally forms as a result of a combination of factors, consisting of surface-active agents, agitation, and the characteristics of the liquid stage. Surfactants reduced the surface stress of the liquid, assisting in the formation of bubbles that can integrate and stabilize. Frustration, whether from mechanical mixing or gas intro, boosts bubble development, bring about raised foam volume.

Recognizing the auto mechanics of foam formation is vital for markets aiming to optimize their processes. By identifying the certain conditions that promote foam generation, organizations can apply strategies to minimize its impacts.

Sorts Of Defoamers Available

Different kinds of defoamers are available to resolve the difficulties presented by foam in industrial applications. defoamers. Generally categorized, defoamers fall under 3 categories: silicone-based, non-silicone-based, and natural defoamers

Silicone-based defoamers are renowned for their efficiency and security throughout a variety of temperatures and pH levels. They are usually made use of in applications where solid foam reductions is needed, such as in adhesives, coverings, and paints. Their low surface tension permits quick foam collapse.

Non-silicone-based defoamers, typically made from organic compounds, supply a choice for applications sensitive to silicone residues. These defoamers can be further divided into polyether and ester types, each customized to fulfill certain formula needs. Non-silicone defoamers are regularly utilized in food processing and personal care products due to their compatibility with numerous formulas.

All-natural defoamers, derived from plant or animal sources, are acquiring grip due to their eco-friendly profile. These products are especially appealing in applications where regulative compliance and sustainability are paramount, such as in agrochemicals and biotechnology.

Picking the best kind of defoamer is crucial for optimizing efficiency and making certain compatibility with specific applications.

Key Application Factors To Consider

When selecting a defoamer, it is important to take into consideration the particular application demands to make certain optimum performance. defoamers. Different sectors have unique requirements, such as food handling, pharmaceuticals, or wastewater therapy, and each application may call for distinct defoaming properties

Trick variables to assess include the tool in which the defoamer will certainly be utilized, whether it is water-based, oil-based, he said or a mix thereof. The temperature and pH levels of the application can additionally greatly influence the efficiency of a defoamer. In addition, compatibility with various other chemicals existing in the system is important to stop damaging responses that can jeopardize efficiency.

An additional vital factor to consider is the lathering actions of the specific system. Recognizing whether the foam develops swiftly or slowly can assist the selection of a defoamer that targets the origin efficiently. The wanted speed of defoaming can influence the selection, as some applications require quick action while others might tolerate slower defoaming procedures.

Lastly, regulative and ecological considerations must not be neglected, specifically in sectors with rigorous compliance needs. Choosing a defoamer that straightens with these elements ensures both efficiency and security in the application.

Performance Screening Approaches

Reviewing the performance of a defoamer requires an organized strategy to testing that precisely determines its efficiency in specific applications. Different performance testing techniques can be utilized to determine the optimum defoamer for an offered solution.

One common technique is the bubble test, which evaluates the defoamer's capability to lower foam quantity in time. This test involves generating a stable foam and after that including the defoamer to observe the price of foam collapse. One more technique is the vibrant foam examination, where foam is generated under controlled conditions to mimic real-world application scenarios. This technique provides insights right into exactly how the defoamer performs under differing shear conditions.

Inevitably, picking the suitable efficiency testing approach depends on the specific application and the kind of foam being resolved. Each method offers important data that can guide solution modifications and boost the performance of the defoamer in functional applications.

Ideal Practices for Option

Next, take into consideration the defoamer's efficiency in terms of rate of action and determination. A quick-acting defoamer might be necessary for processes where quick foam suppression is vital, while a much more relentless formula could be needed for long term foam control. In addition, evaluate the environmental impact of the defoamer, including its biodegradability and any type of governing conformity requirements.

Conduct tests with picked defoamers to identify their effectiveness in real-world conditions. This action is vital to confirm that the picked product meets efficiency expectations. Lastly, talk to manufacturers or vendors for technological assistance and support, as they can give beneficial insights into item formulas and application techniques. By sticking to these ideal techniques, you can enhance foam their website control performance and guarantee the durability of your procedures.

Conclusion

In recap, picking the appropriate defoamer requires a thorough evaluation of numerous variables, consisting of foam type, tool, operating problems, and ecological considerations. Understanding the special attributes of foam formation additional resources and the readily available defoamer alternatives is essential. Additionally, utilizing reliable performance testing approaches and adhering to finest methods during the choice process will enhance the likelihood of accomplishing optimal defoaming outcomes. Ultimately, a well-informed option strategy will certainly attend to particular application demands and minimize foaming obstacles properly.

Choosing the suitable defoamer for certain application needs is a nuanced procedure that demands mindful consideration of several variables, such as the foam medium, operating, and kind problems.Choosing the right defoamer is critical for accomplishing ideal performance in foam control applications. A quick-acting defoamer may be required for procedures where fast foam reductions is essential, while an extra persistent solution may be required for prolonged foam control.In recap, selecting the proper defoamer requires a comprehensive analysis of various factors, consisting of foam kind, medium, operating problems, and environmental factors to consider. Comprehending the one-of-a-kind qualities of foam formation and the available defoamer alternatives is vital.

Comments on “How Defoamers Enhance Efficiency in Manufacturing and Production”